Description

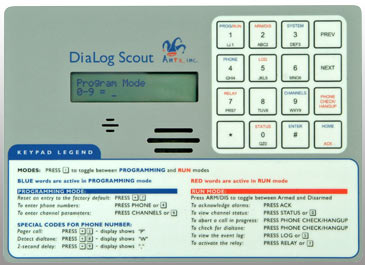

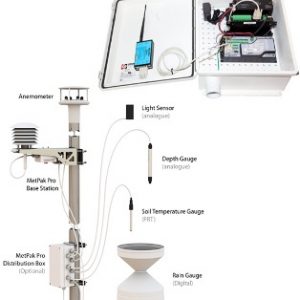

Integral keypad, LCD display, Wall-mount plastic enclosure, Listen-In capability, Event log – keeps history of what has occurred,Textual channel names so you know exactly what channel is in alarm, Pre-programmed or user-spoken messages for unique alarm notification for each condition, Alarm Notificationo Phone, cell phone or pager User-recorded messages for each input, 8-phone numbers to call on alarm, Power fail alarm, Low battery level alarm,Local notification of alarm conditions – Remote Operations Call-in for status, Call-in to acknowledge alarms, Call-in to program messages, phone numbers and channels – Physical Characteristics Pluggable connectors, Input power 9-12VDC at 500ma (wall-plug power supply included), 12-hour internal backup battery (included) – Programming made simple All programming options are conveniently presented on the LCD display , Call-in to make programming changes by responding to voice-prompts, Options are presented one after another making it easy to setup and modify,Conveniently located on the front panel are the microphone for recording and the speaker for playing back messages.Historical events including all alarms, call-outs, relay controls, and acknowledgements are stored in the Event Log which can be retrieved locally or remotely. Scout Pump Controller Features The Scout Pump Controller, ScoutPC, is a small, dedicated simplex/duplex pump controller with an integrated industrial alarm notification and remote monitoring system. The ScoutPC combines two proven products into a single dedicated unit – the Mercoid Pump Controller and the Antx DiaLog Scout. The Pump Controller provides simplex or duplex control from a level or pressure sensor and the Scout provides monitoring and alarm notification of high/low levels, pump failures, over temperatures, seal failures and more. Control Features – Duplex or Simplex operation – Simple wiring – NEMA or panel-mount – Over-temperature alarms – Seal failure alarms – Fill or Drain applications – Independent on/off setpoints for each pump – Alternation or Lead/Lag operation – Selectable time delay to prevent both pumps from starting at the same time – 4-20ma retransmission of level for recorders or other devices – 24VDC Loop power provided – 2 3-amp relays for local alarms – Controller operation is totaly independent from alarm dialer – Continuous sensor calibration – Open-loop or sensor fault detection – Built-in controller test function – No wiring – Current and historic run-times for each pump – Current and historic daily high- and low-level recordings – Remote call-in to change control setpoints – Remote call-in to retrieve current and historic run-times and current tank level – Alarm calls to 8 phone/pager numbers – Battery backup – Optional cellular phone with or without Internet reporting – LCD display on alarm system to view historic data – Event log records all alarms, calls, acknowledgements and more – Password protection – Alarm on: High and low level Seal failure Over temperature Sensor failure Sensor calibration bad Controller self test failure Primary power failure