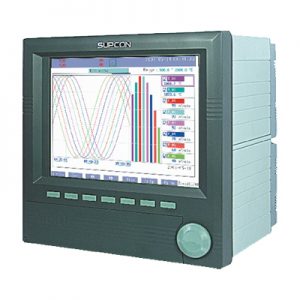

E6500 Data Acquisition Unit

Description

OVERVIEW

Event & Statistics Logs

Up to 512 pieces of custom events, such as valve-open, special alarm and so on, can be logged to analyze. It can be triggered by digital signals.

Up to 32 batches custom statistic messages, such as the maximum, the minimum, the average, alarm frequency, alarm duration of analog signals can be logged for analysis. It can be logged manually or triggered by digital signals.

Mathematical Functions

Up to 60 mathematical functions are offered to develop custom solutions. These functions, such as arithmetic, Boolean, mathematical calculation, relational operation, complicated logical function, statistic function, timer operation, etc., can be applied with control modules to realize very complicated control.

Powerful Controlling Modules

4 PID modules, 3 setpoint program modules and 6 ON/OFF modules are provided.

With mathematical expression, PID modules can be configured as complex control strategies such as cascade, ratio, split ranging, feed forward, averaging control, 3-element control for process industries. Some control modes such as step, logic, batch, and timing for automation control of equipments are provided, too.

The setpoint program modules can vary the setpoint in a controlled manner over a set period of time. The output of the program is divided into a flexible number of segments – each being a unit of time, and can be the setpoint value of PID module.

The ON/OFF modules are always used for a single object with a large time constant and a small dead time, such as temperature control for constant temperature box and heat-up furnace, water level control for tank, pressure control for air compressor and so on.

Mass Flow Compensation

For obtaining a more precise fluid flow measurement, the E6500 provides 5 preset selections, SHS (superheated stream), STS (saturated steam), GAS (ideal gas), LPC (linear pressure compensation), and LTC (linear temperature compensation).

Removable Media

Up to 32GB USB flash disk is accepted to transfer the history data, the settings, the logging data and the monitoring displays from E6500 to PC.

Communication

2 serial communications are offered including RS-232C and RS-485 using the Modbus protocol. Additionally, Ethernet with TCP/IP protocol and GPRS with RS-232C is also provided.

| 12 Analog Inputs 4 Analog Outputs 2 Digital Inputs 12 Digital Outputs 2 Pulse Inputs 4 PWM Outputs 3 Setpoint Program Modules 4 PID Control Modules 6 ON/OFF Control Modules |

8 Timers 60 Functions 0.125s Sampling Period 128MB Inbuilt Memory Event & Statistics Logs Flag Logs Message Logs RLZ Temperature Formula Mass Flow Compensation |

Auto-Tuning 4-Level User Authority Settings Backup Stop Recording Manually/ Automatically RS-232C/RS-485 Interface Ethernet Interface Usb Flash Disk Prink |